News

Site Editor

Site

/uploads/image/65596ff804643.png

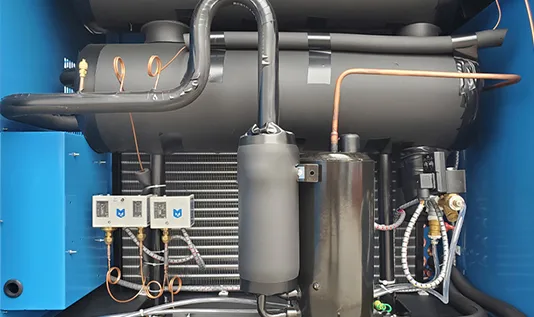

This article delves into the reasons why compressed air demands drying, explores different types of compressed air dryers , highlights leading manufacturers, and emphasizes the significance of refrigerated and line dryers in maintaining peak performance and equipment longevity.

Site

/uploads/image/65596ff804643.png

This article delves into the reasons why compressed air demands drying, explores different types of compressed air dryers , highlights leading manufacturers, and emphasizes the significance of refrigerated and line dryers in maintaining peak performance and equipment longevity.

Why Does Compressed Air Require a Dryer?

Views: 499

Author: Site Editor

Publish Time: 2024-05-24

Origin: Site