News

Site Editor

Site

/uploads/image/65596ff804643.png

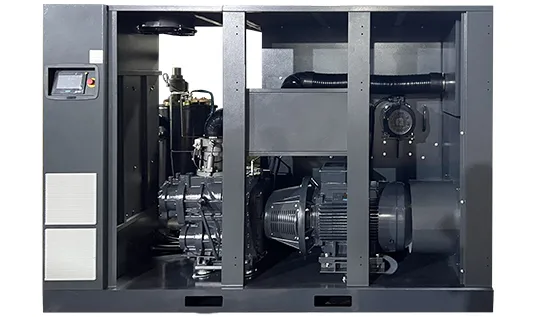

In the realm of industrial operations, rotary screw air compressors are workhorses that power numerous processes. To ensure their continued reliability and efficiency, proper maintenance and care are paramount. This comprehensive guide explores the essential steps for maintaining screw type air compressors , emphasizing the critical role these practices play in prolonging service life.

Site

/uploads/image/65596ff804643.png

In the realm of industrial operations, rotary screw air compressors are workhorses that power numerous processes. To ensure their continued reliability and efficiency, proper maintenance and care are paramount. This comprehensive guide explores the essential steps for maintaining screw type air compressors , emphasizing the critical role these practices play in prolonging service life.

Maintenance and Care of Screw Air Compressors: The Key to Prolonging Service Life

Views: 599

Author: Site Editor

Publish Time: 2024-04-15

Origin: Site