News

Site Editor

Site

/uploads/image/65596ff804643.png

A variable speed screw air compressor is a type of industrial equipment designed to produce compressed air. It uses a helical rotor design to compress air and a variable speed drive (VSD) to adjust the motor's speed according to the demand for compressed air. This makes it highly efficient as it can closely match the air supply to the system requirements, reducing energy waste during periods of low demand. This article takes you to a deeper understanding of Olymtech's variable speed screw air compressor from a technical perspective.

Site

/uploads/image/65596ff804643.png

A variable speed screw air compressor is a type of industrial equipment designed to produce compressed air. It uses a helical rotor design to compress air and a variable speed drive (VSD) to adjust the motor's speed according to the demand for compressed air. This makes it highly efficient as it can closely match the air supply to the system requirements, reducing energy waste during periods of low demand. This article takes you to a deeper understanding of Olymtech's variable speed screw air compressor from a technical perspective.

Olymtech CPM variable speed screw air compressor technology introduction

Views: 677

Author: Site Editor

Publish Time: 2024-07-15

Origin: Site

A

variable speed screw air compressor

is a type of industrial equipment designed to produce compressed air. It uses a helical rotor design to compress air and a variable speed drive (VSD) to adjust the motor's speed according to the demand for compressed air. This makes it highly efficient as it can closely match the air supply to the system requirements, reducing energy waste during periods of low demand.

This article takes you to a deeper understanding of Olymtech's variable speed screw air compressor from a technical perspective.

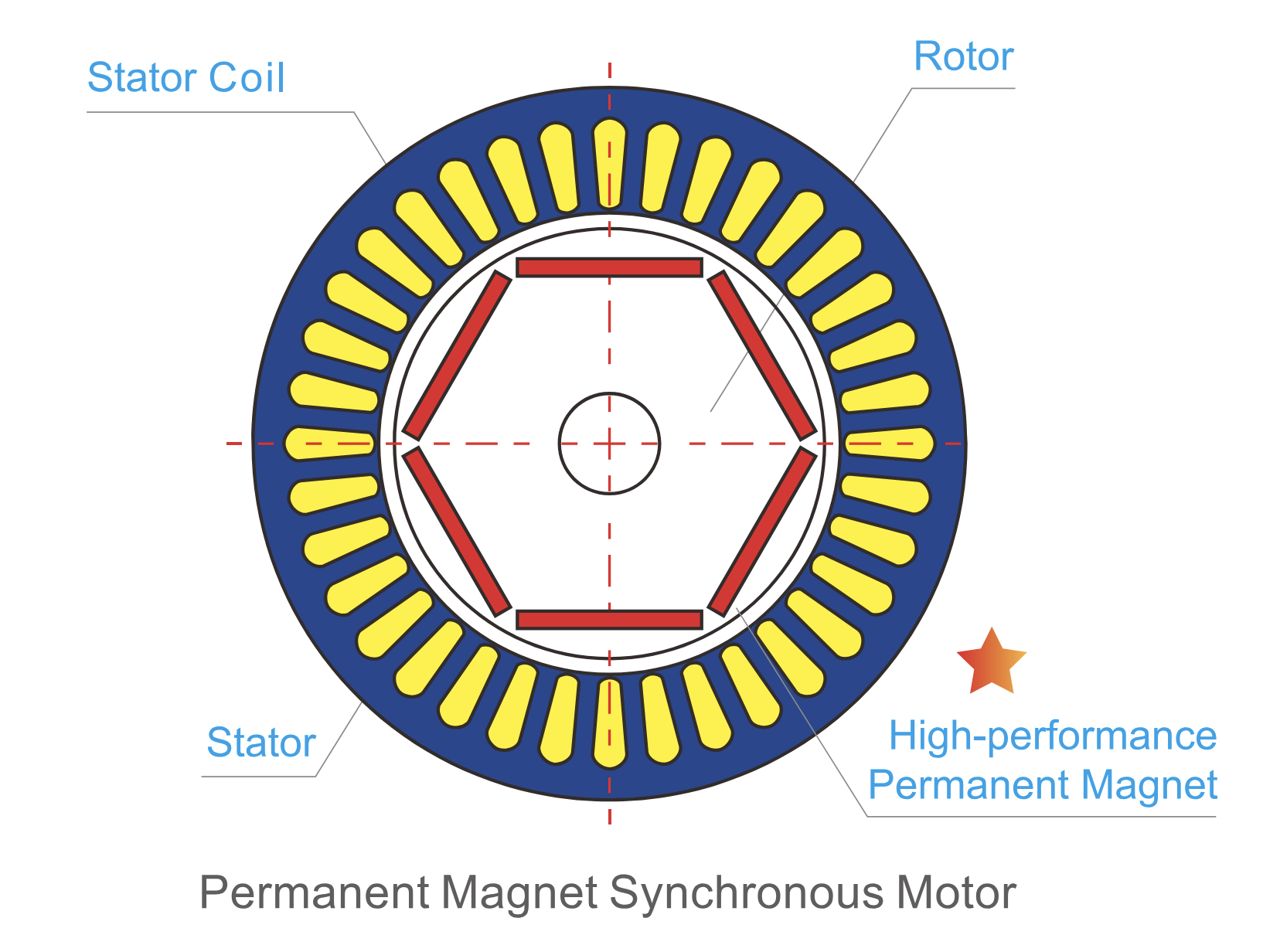

Olymtech's variable speed screw air compressor uses a

Permanent Magnet Synchronous Motor

A

dvantages of

Permanent Magnet Synchronous Motor

1,

Adopts the high efficiency NdFeb permanent magnet, The service life is more than 15 years

2,

Reduce the working pressure of the system. The constant voltage is more efficient

3,

Wider range of the AC voltage(300V440V). The compressor can run normally and it won’t stop in this range.

4,

Stator Coil: Using the wire which is specialized in the inverter. Excellent insulation, longer service life.

5,

No power consumption when it is unloading. No unloading, No electricity waste.

6,

Can adjust the discharge air volume according to the air pressure.

7,

When the use of air is not stable, average energy saving reaches to 35-50%.

8,

Permanent magnet synchronous motor for higher efficiency

9,

Colour touch screen: Customised smart touch screen and control module. Easy to operate.

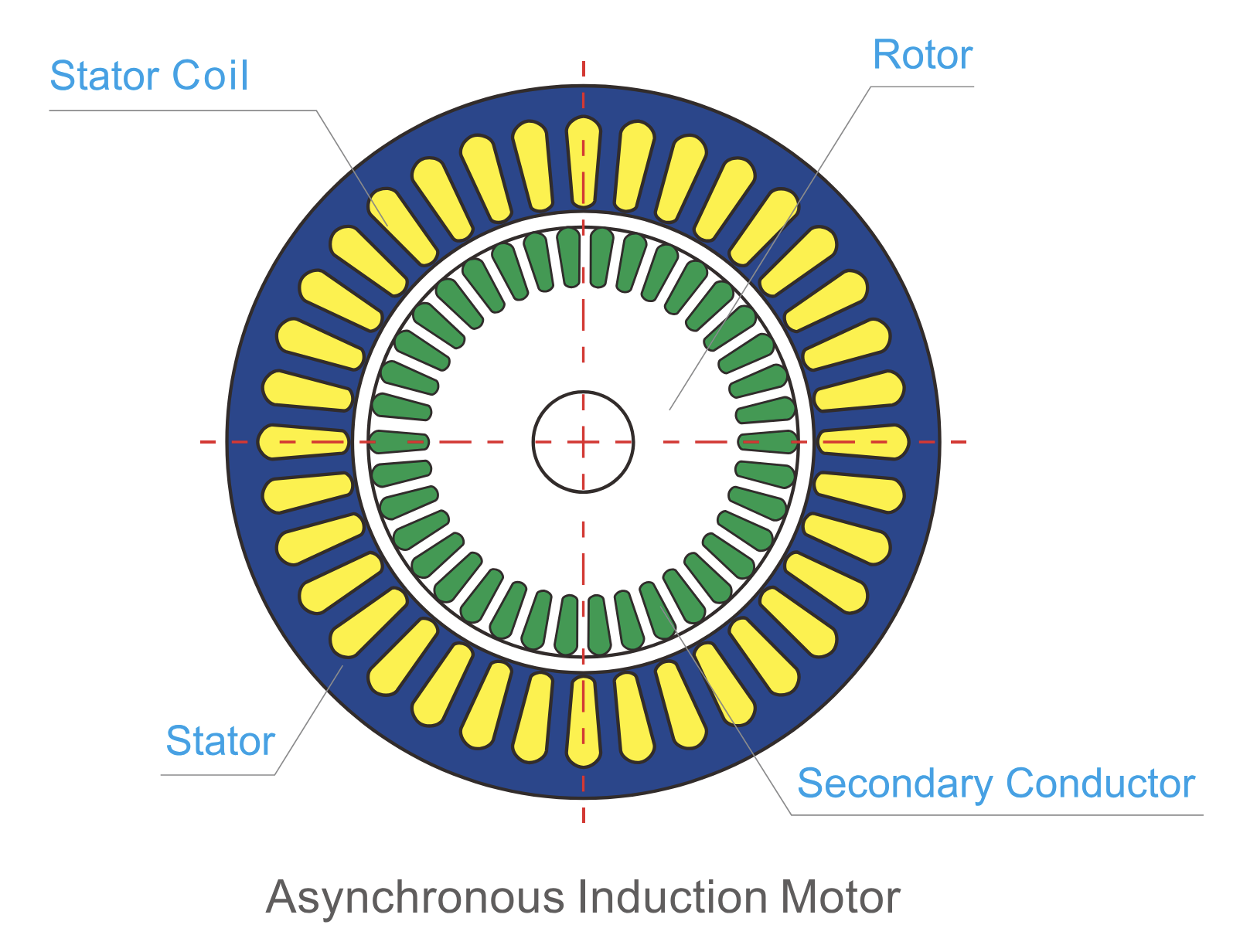

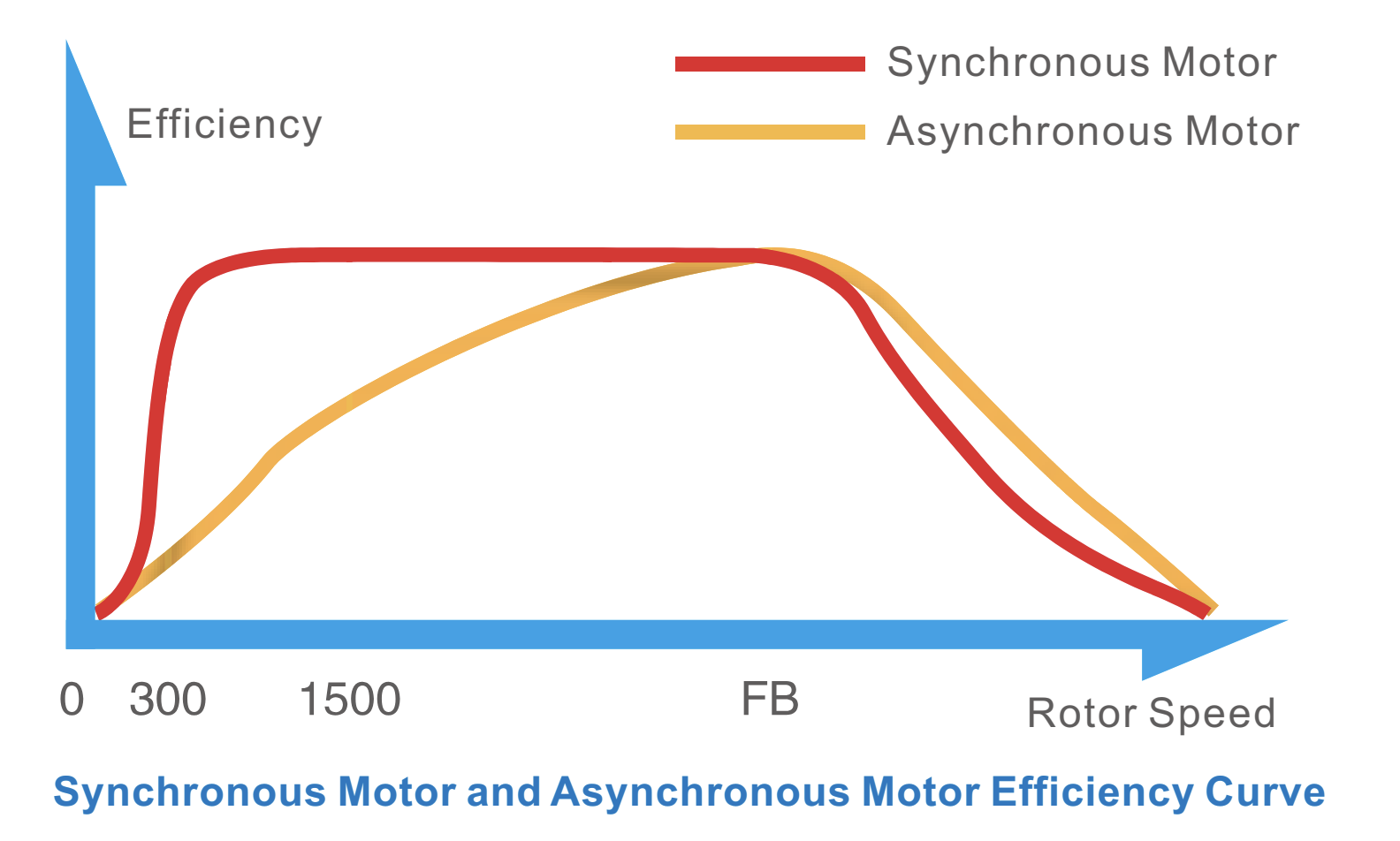

Comparison between permanent magnet synchronous motor and ordinary asynchronous motor

Magnetic field is the foundation of the motor to realize the electricity energy conversion. Depending on the way to establish the magnetic field, it divides into the electric excitation motor and permanent magnet motor. Compared to the electric excitation motor, the permanent magnet motor has the advantages as below:

1, High Efficiency

(1) It cancels the loss of the excitation system which improves efficiency 5%-12%.

(2) The power factor is high , the force ratio of inertia is high.

(3) The motor is in directed drive, without the speed slip loss, No need for the bearing and connection to drive, that can improve more than 3%

efficiency.

(4) When in light loading, the PM motor can improve 15-35% efficiency as the same specifications of induction motor. High efficiency in light or heavy load.

At present, Olymtech is use the level 1 energy saving PM motor.(Ie3)

2, Low Noise

(1) With the design in magnetic field,magnetic density distribution,wider working frequency range, lower operation noise.

(2) The air pressure is constant, open loop vector control, it can adjust a

wide range of discharge air volume immediately.

3, Compact Structure ,Small Size,Light Weight

(1) It cancels the excitation winding and the excitation power (magnetic pole core ).

(2) The structure is simple, reliable operation and easy maintain.

4, High Precision, Fast Response

5, Bigger Starting Torque

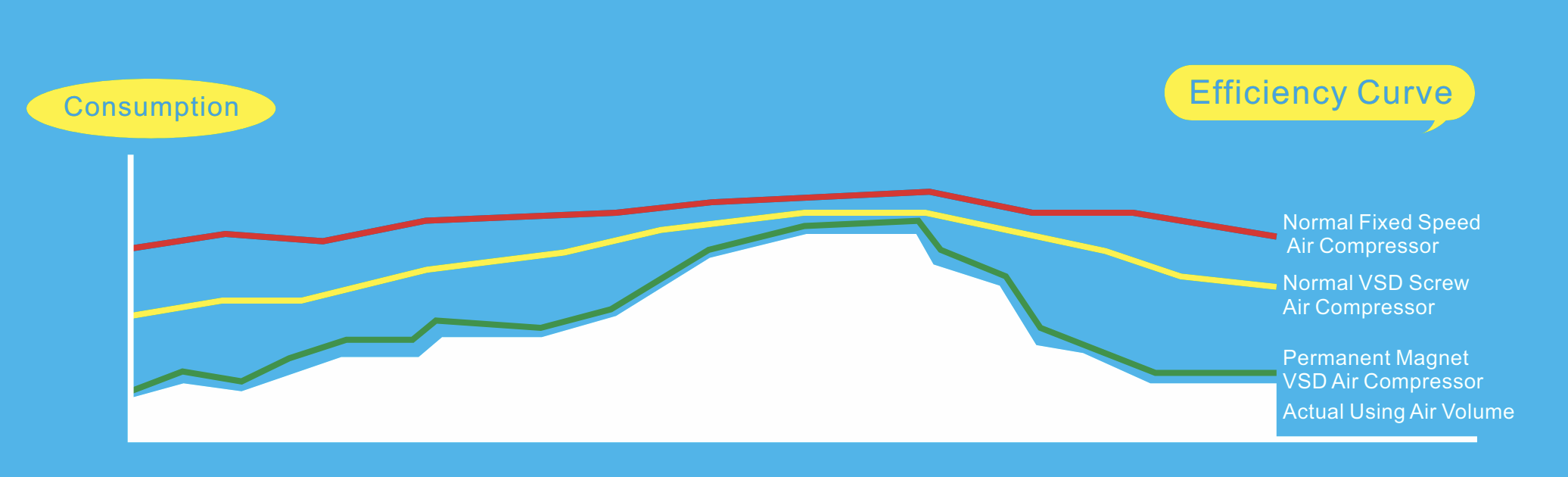

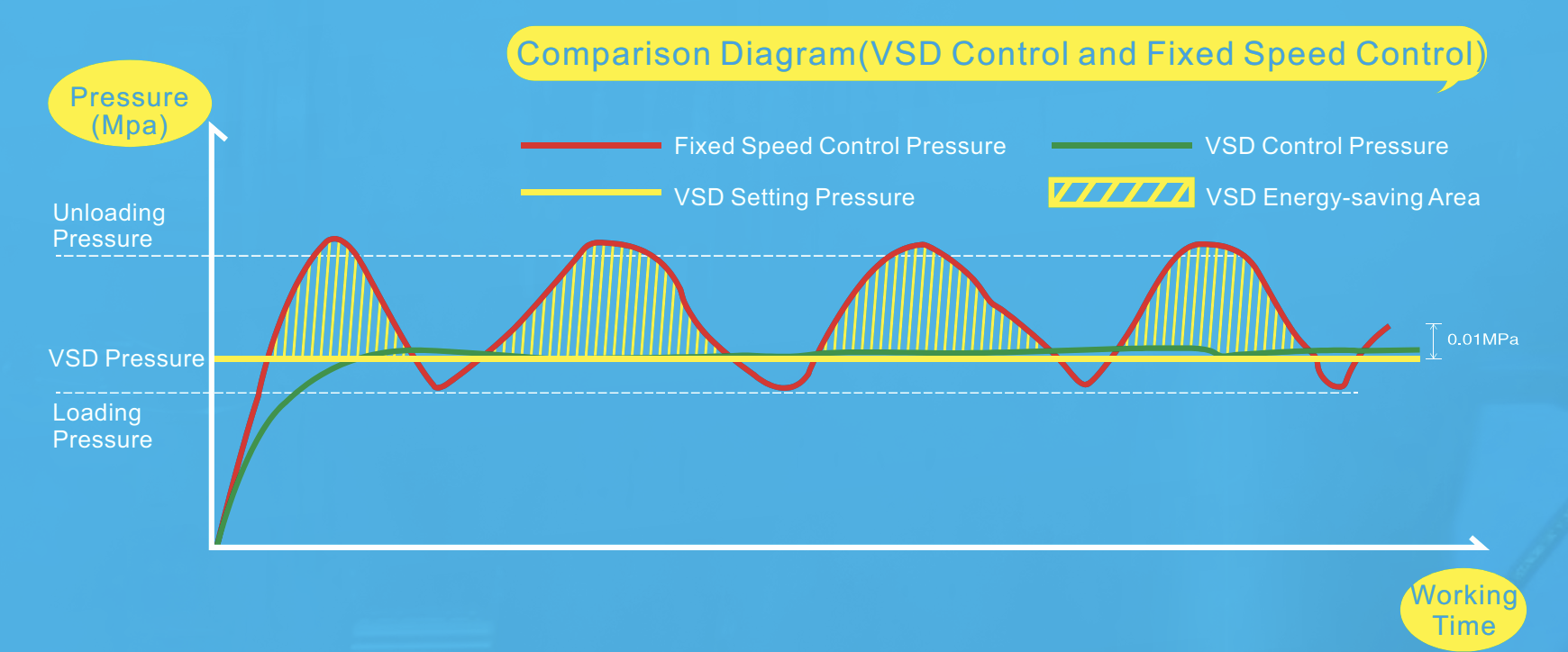

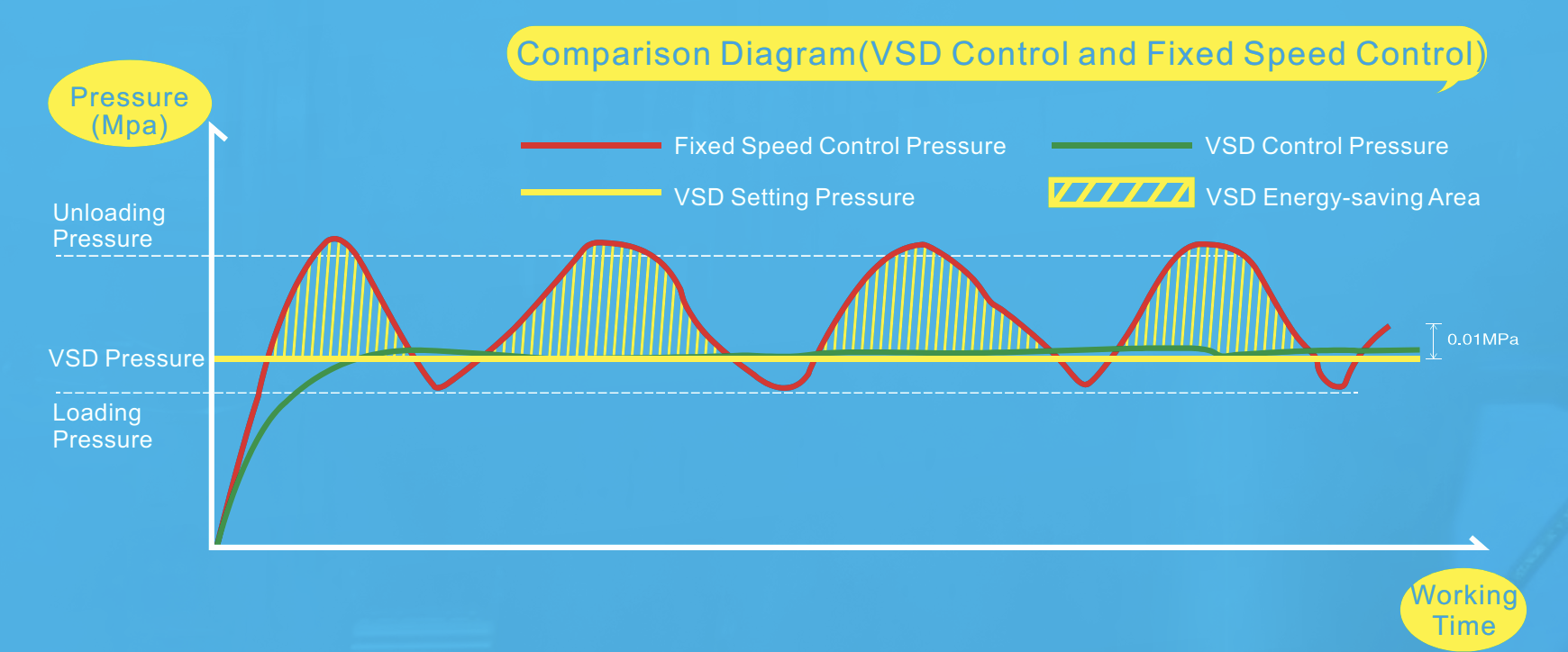

Variable speed air compressor compared to fixed speed compressor

Compared with the fixed speed compressor, PM VSD compressor can save electric charge more than 74,000 degree/year.

10836kw.h + 52800kw.h + 10836kw.h =74472kw.h/year

(Above data is the 37kw

screw air compressor

Industry data, your factory actual saving value is depends on actual using condition .)

Variable speed

screw

air compressor

Energy Saving Solution

Smart inverte can save variable speed air compressor 35% energy

A wide speed control range of frequency converter prevents unnecessary power consumption for no-load operation.

|

|

|

Permanent magnet motor

save

energy 2-5%

High efficiency IE3 permanent magnet motor reduces energy costs

|

No unnecessary pressure

save

energy

3-15%

Constant pressure setting reduce the pressure drop, 1bar of unnecessarily high pressure correopnds to about 7% of the energy.

|

|

|

Lossless direct drive

save

energy 3-15%

The direct connect in between the airend and motor has none of the transmission losses.

|

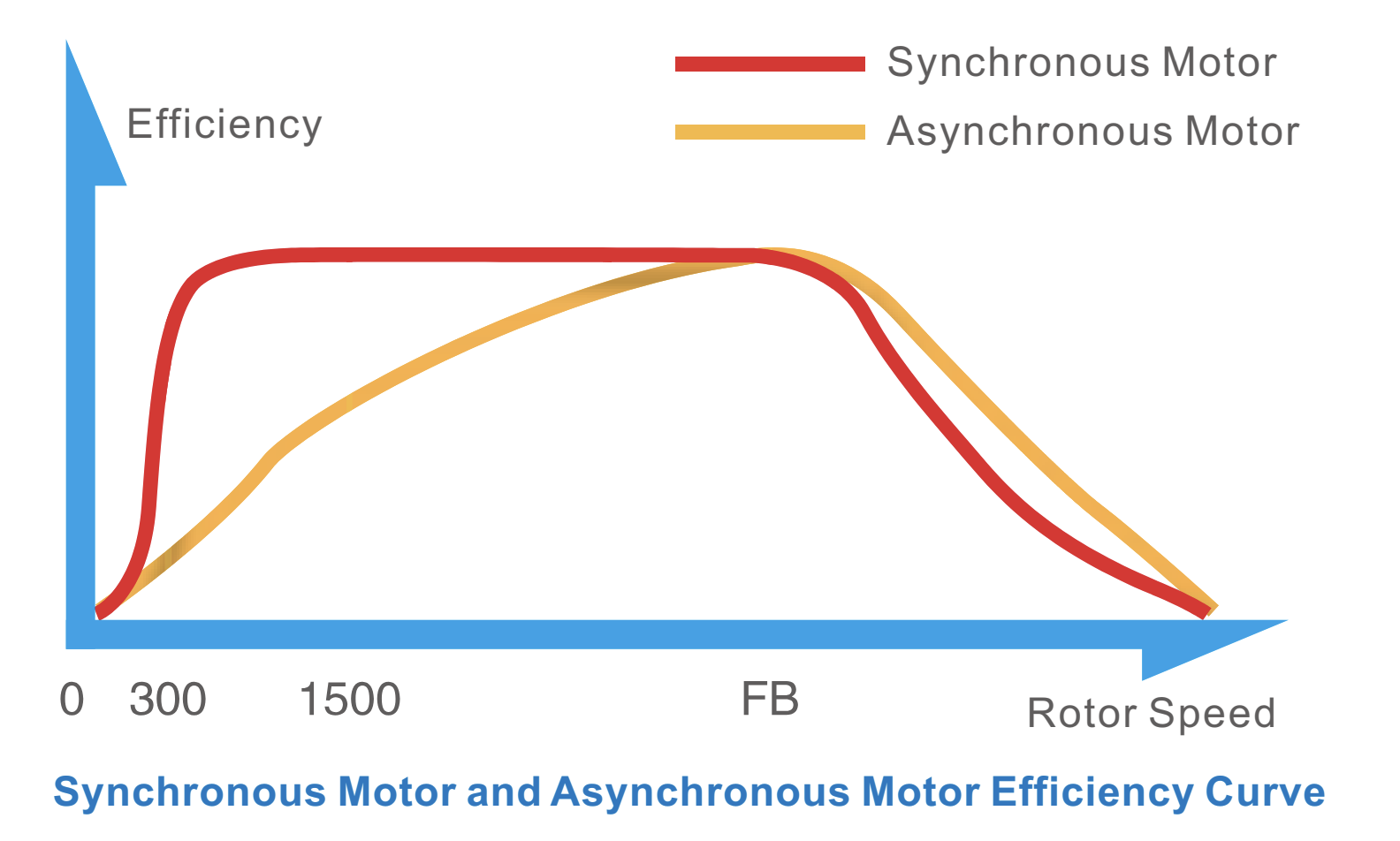

Application of Permanent Magnet Motor

1, Olymtech uses the high efficiency permanent magnet synchronous motor. Compared with the normal asynchronous VSD motor, energy saving performance is more outstanding. The full load efficiency of a 37Kw PM motor is 97%, however the efficiency of same level asynchronous motor is only 92% ,it may save 5% energy.

2, It can save electricity about 10836 degree/year when we use the PM compressor in 37KW.

When in low speed, the permanent magnet synchronous motor efficiency won’t be changed, but normal asynchronous

motor efficiency will be lower. Average PM compressor can save energy 7%-11%.

3, 37KW means the shaft power of the main motor. The actual input power is (37kw x 1.15 service factor) =43KW. If the compressor works for 6000 hours per year, 60% loading rate:

1year electric saving:

6000h x 43kw x 60% (loading rate) x7% = 10836kw.h

Suspect electric charge USD0.2/kw.h, 1year save money:10836kw.h x USD0.2/kw.h = USD2167.00

Application of VSD Technology

1, When air compressor unloads, it consumes electric power approximately 50% but giving you nothing in return.

2, For example a 37Kw compressor, if the loading rate is 60%, it means the unloading rate is 40%, it will waste 22kw when in unloading (full load is 37kw x 1.15 service factor x 50% =22kw). If the compressor runs 6000 hours per year, this compressor has 40% unload, it consumes 22kw power during the 2400hours, it may waste electricity in 52800kw.h

6000h x 40% (unloading rate) x 22kw = 52800kw.h

3, To use Olymtech PM compressor C37PM, wastage problem is solved, you can save electric 52800kw.h/year! Because Inverter automatically adjusts the motor speed, thus to changes the air supply as the air demand floating, no unloading wastage.

* Above data is the Industry data, the actual saving value depends on actual use.

Without Pressure Loss

1, A compressor pressure is 0.8Mpa, it’s actual unloading pressure is 0.8Mpa, and the loading pressure is 0.65Mpa, that means pressure 0.65Mpa is enough for factory using.

2, Adjust C37PM pressure to 0.65Mpa, which can save electricity 11340kw.h/year.

3, To reduce system pressure every 0.14barg, it can save 1% energy. This equates 7% as an example.

37KW means the shaft power of the main motor. The actual input power is (37kw x 1.15 service factor) =43KW. If the compressor works for 6000 hours per year:

1year electric saving:

6000h x 43kw x 60% (loading rate) x7% = 10836kw.h

Suspect electric charge USD0.2/kw.h, 1year save money:10836kw.h x USD0.2/kw.h = USD2167.00

Compared with the normal frequency compressor, PM

variable speed air compressor

can save electric charge more than 74,000 degree/year.

10836kw.h + 52800kw.h + 10836kw.h = 74472kw.h/year

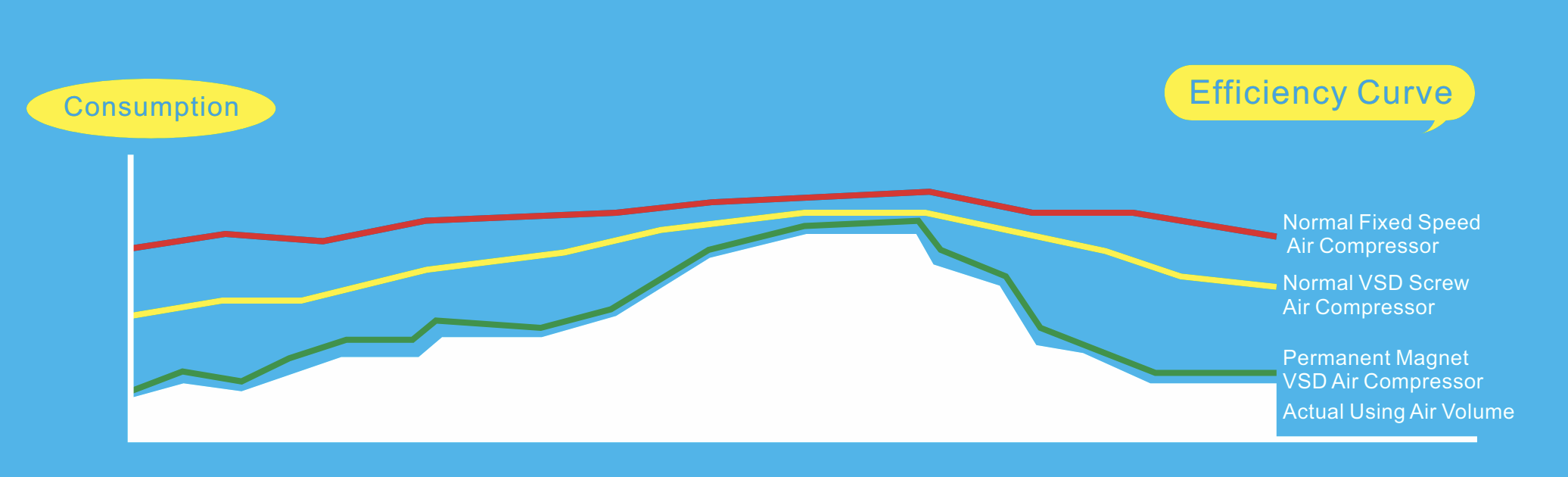

Why Choose Olymtech VSD PM Compressor?

Compared with the normal fixed speed and normal

VSD screw air compressor

, in the small loading rate, the PM screw compressor has lower energy consumption and more energy saving.

Most factories will choose a compressor with 20% higher air volume as they consider pressure loss. There is a big fluctuation in the air consumption of any time(different time, every day, every year). It may result most of the loading rate is about 50% to 70%. The User spends unnecessary electricity charge, which means they can not reduce the product cost. Now the material cost is no longer the key product cost, the electricity charge had been the key product cost. So saving electricity means saving products cost, which make your products more competitive.

Most factories will choose a compressor with 20% higher air volume as they consider pressure loss. There is a big fluctuation in the air consumption of any time(different time, every day, every year). It may result most of the loading rate is about 50% to 70%. The User spends unnecessary electricity charge, which means they can not reduce the product cost. Now the material cost is no longer the key product cost, the electricity charge had been the key product cost. So saving electricity means saving products cost, which make your products more competitive.

Air-ends operate almost silent

1, Using advanced structural design, optimization of fluid and soundabsorbing materials and other methods, realise the ultra low

operating sound.

2, The fan can be controlled by the inverter, this can further reduce the noise(optional).

3, Consider the sound pressure, sound quality, the volume of noise

and other countermeasures, makes the noise drop to a minimum

Level, ensures it is suitable for any factory.

Air-ends operate almost silent

1, Using advanced structural design, optimization of fluid and soundabsorbing materials and other methods, realise the ultra low

operating sound.

2, The fan can be controlled by the inverter, this can further reduce the noise(optional).

3, Consider the sound pressure, sound quality, the volume of noise

and other countermeasures, makes the noise drop to a minimum

Level, ensures it is suitable for any factory.

Real energy-saving products- Olymtech Permanent Magnet Motor Variable Speed Screw Air Compressor

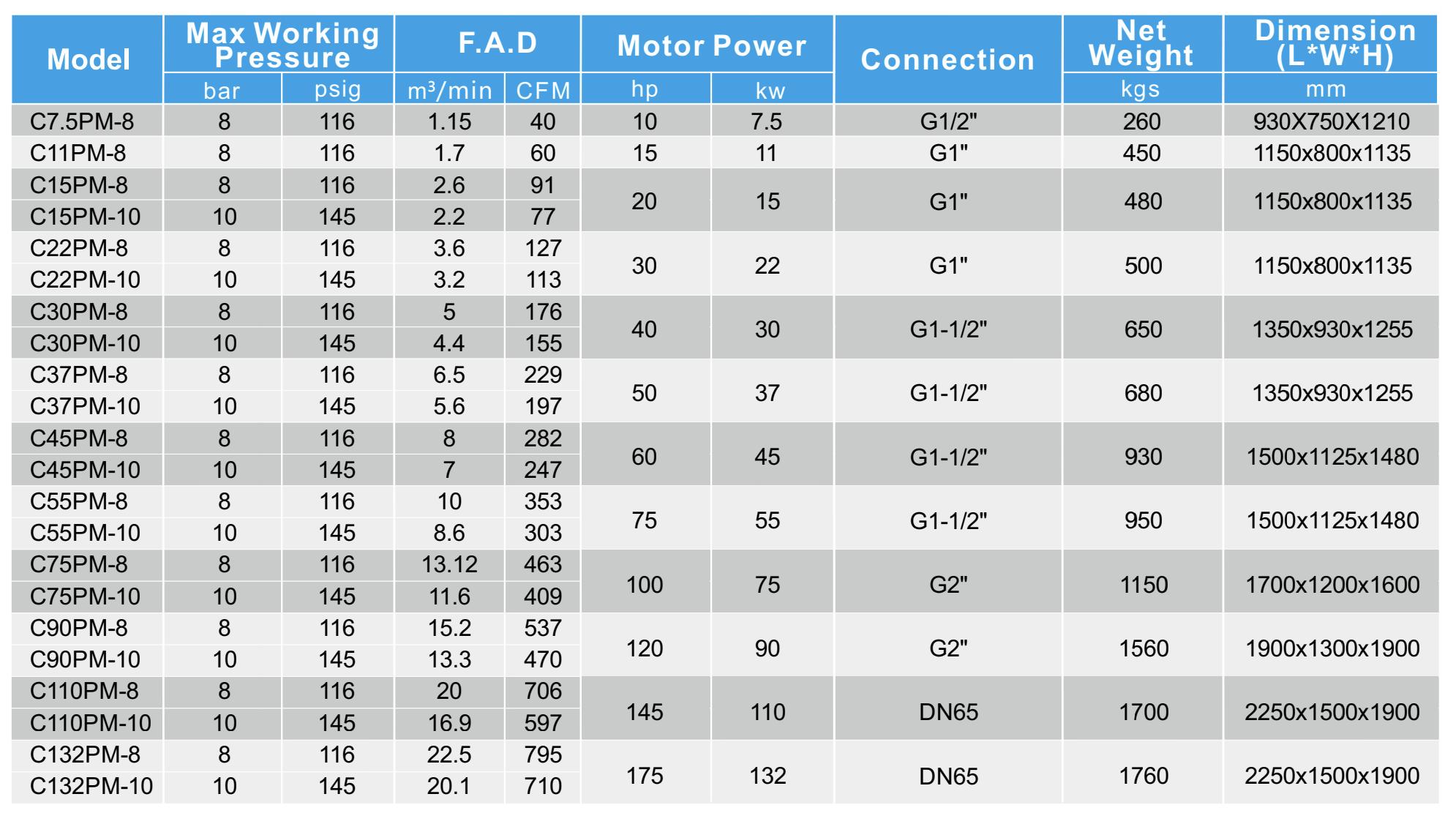

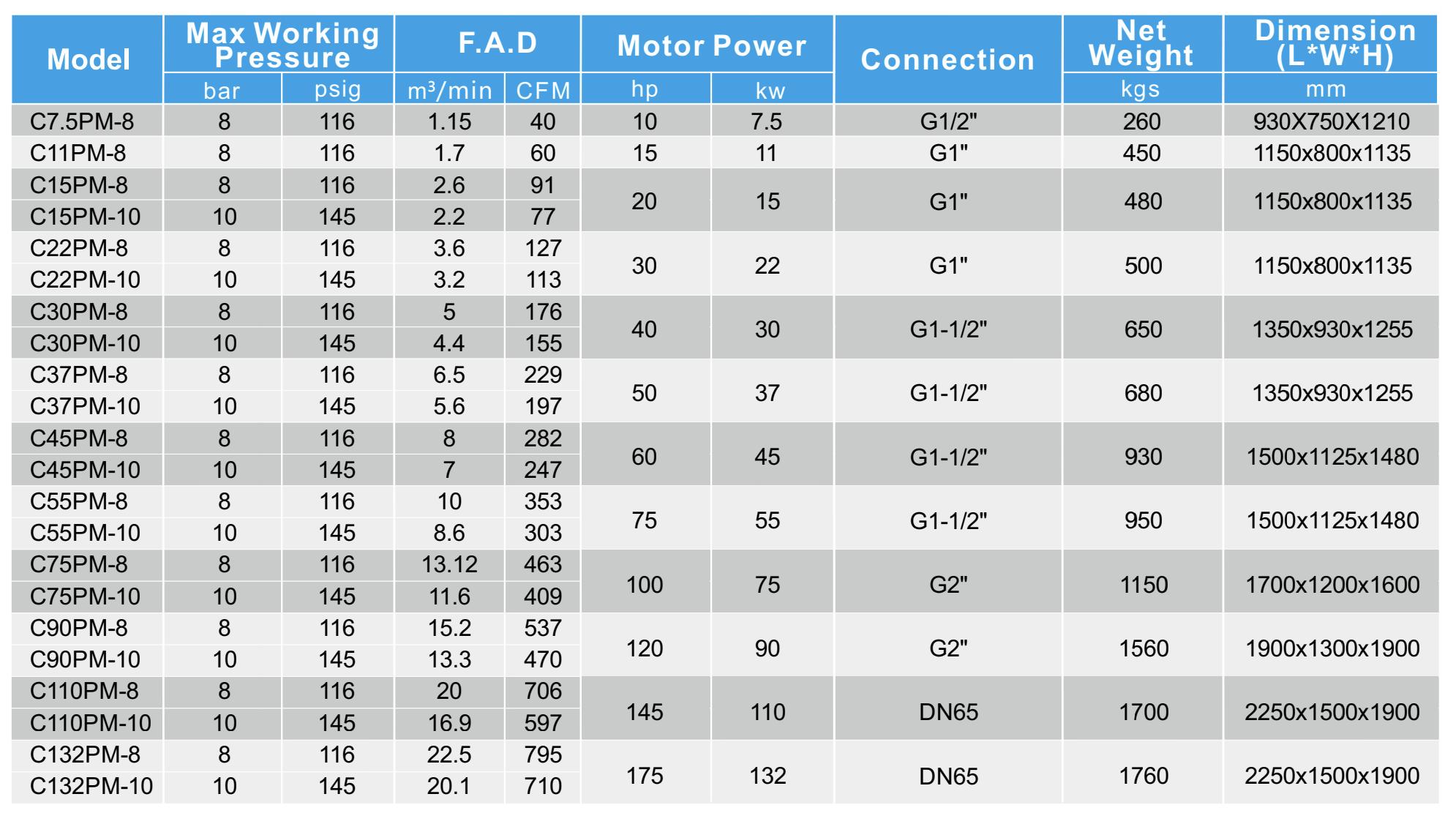

Technical Parameter

CPM Series Permanent Magnet VSD Screw Air Compressor

■ According to the standard of GB19153-2009

■ Compressor Stage: One Stage Compression

■ Standard Power Supply: 380V/50Hz/3Ph

■ Exhaust Temperature: Ambient Temperature + 15 ℃

■ Please contact us for any specification that is not within the above mentioned standards.

■ According to the standard of GB19153-2009

■ Compressor Stage: One Stage Compression

■ Standard Power Supply: 380V/50Hz/3Ph

■ Exhaust Temperature: Ambient Temperature + 15 ℃

■ Please contact us for any specification that is not within the above mentioned standards.