- Product Description

- Technical Parameter

- Video

- Catalogue Download

- Case

Product Description

WHY NEED TO USE THE REFRIGERATED AIR DRYER

Usually compressed air contains 100% vapor, these vapors are condensed together when the air would be cooled. The condensed water not only damages the compressor system, reduces tool efficiency,but also destroys your terminal products, corrodes piping and increases your maintenance costs.

More than 90L water will enter into the compressor system everyday if without the air dryer refrigerated air dryer removes approximately 90% of water and ensures your application in good performance.

Air dryer operation process

|

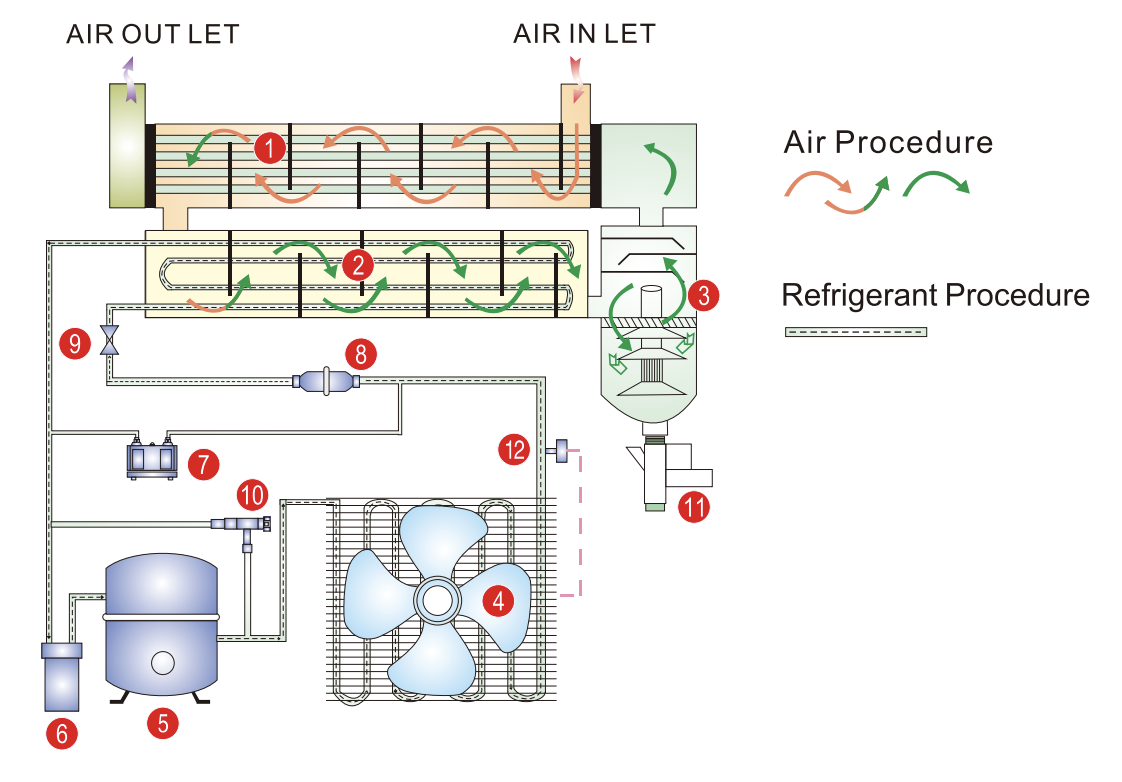

1.Pre-cooler/Heat Exchanger 2.Evaporator 3. Air /Water Separator 4.Air-cooled Condenser 5.Refrigerant Compressor 6.Refrigerant Reservoir 7. High-low Pressure switch 8.Dry Filter 9.Expansion Valve (Capillary) 10. Hot Gas Bypass Valve 11.Electric Auto-Drain 12. High Pressure Switch |

|

Air Procedure:

The compressed air from "AIR INLET" enters into air drver and goes through (1) Pre-cooler the compressed air will be pre-cooled first, after that it flows through (2) Evaporator to get further cooler, the vapor of the compressed air is condensed because the air gets cool, when the cooled compressed air passes (3) Air/wateseparator, water will be discharged by (11) Electric auto-drain automatically. At last the dry and cool compressed air enters into the copper pipe of (1) Pre-cooler again, the outlet air and inlet air exchange the temperature in pre-cooler. Dry compressed air out from "AIR OUTLET”

Refrigerant Procedure:

The refrigerant will be compressed by (5) Refrigerant compressor, after that it is a high temperature and high pressure vapor, the refrigerant vapor enters into (4) Air-cooled condenser to gets lower temperature, this moment refrigerant from a vapor to a liguid state, and then liguid refrigerant go through (8) Dryer filter to get purer, and then it pass by the (9) Expansion valve, the pressure of refrigerant becomes lower. Gas and liquid mixed refrigerant flow into copper pipe of (1) Evaporator to low down the compressed air temperature, finally refrigerant gets back to (5) Refrigerant reservoir, this is a circular process.

Technical Parameter

| Model | Air capacity | Compressor Power | Power Supply | Air Connection | Dimension(LxWxH) | |

|---|---|---|---|---|---|---|

| - | m¾min | CFM | hp | v/hz/ph | kg | mm |

| BL0005 | 0.8 | 28 | 0.25 | 220v/50hz/1ph | 50 | 400x800x640 |

| BL0010 | 1.8 | 64 | 0.35 | 220v/50hz/1ph | 56 | 400x800x640 |

| BL0020 | 2.8 | 99 | 0.5 | 220v/50hz/1ph | 65 | 400x800x780 |

| BL0030 | 3.8 | 134 | 0.75 | 220v/50hz/1ph | 68 | 400x800x780 |

| BL0040 | 5.5 | 194 | 1.25 | 220v/50hz/1ph | 90 | 500x860x880 |

| BL0060 | 6.8 | 240 | 1.5 | 230v/50hz/1ph | 95 | 500x860x880 |

| BL0080 | 8.8 | 311 | 2 | 220v/50hz/1ph | 130 | 700x900x1000 |

| BL0100 | 11.5 | 406 | 2.5 | 220v/50hz/1ph | 135 | 700x900x1000 |

| BL0120 | 14 | 494 | 3 | 380v/50hz/3ph | 160 | 700x1000x1000 |

| BL0150 | 16 | 565 | 9 | 380v/50hz/3ph | 165 | 800x1000x1000 |

| BL0200 | 22.8 | 805 | 5 | 380v/50hz/3ph | 250 | 700x1450x1160 |

| BL0250 | 28.5 | 1007 | 6 | 380v/50hz/3ph | 300 | 700x1450x1160 |

| BL0300 | 35 | 1236 | 8 | 380v/50hz/3ph | 400 | 1800x1000x1360 |

| BL0400 | 45 | 1589 | 10 | 380v/50hz/3ph | 500 | 2000x1000x1360 |

| BL0500 | 55 | 1943 | 12.5 | 380v/50hz/3ph | 600 | 2200x1100x1480 |

Case

In the air dryer product user case display section, we carefully showcased the application examples of refrigerated air dryers in different industries, witnessing the excellent performance of our products in improving air quality and ensuring production stability. Each case is a strong proof of the reliability and effectiveness of our products. Through these real stories, you will understand how our dryers help customers improve production efficiency and reduce maintenance costs.

EN

EN

Download

Download